Race 57 Super Corsair

So what is my challenge for the month of April….

This is a Hanger9 .60 size Corsair ARF that will be turned into the Race 57 Super Corsair for a long time repeat customer…stand-off scale of course. Lets get started…

race57-002

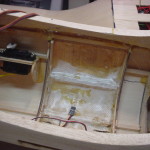

The Race 57 will remain electric powered but this battery hatch will be redesigned and/or relocated.

race57-003

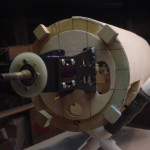

The Century Jet air retracts will be replaced with Lado electrics.

race57-004

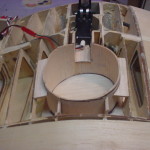

Inside the fuse which will be gutted and reworked.

race57-005

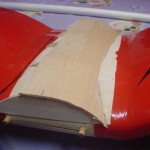

Top side of the wing needs a little work.

race57-006

Canopy area will be reworked to use a P-51 style bubble canopy.

race57-007

Old battery hatch will not be reused.

race57-008

Another shot of the battery hatch.

race57-009

Inside the fuse with the hatch in place.

race57-010

Mechanical tailwheel retract that will be reused but without the arrestor hook.

race57-011

Spaghetti monster of air lines and sound system wiring that will all be removed.

race57-012

Sound system speaker in each wing will be removed.

race57-013

Sheeting around the retracts will be reworked once the new electrics are fitted.

race57-014

Digging out the air retracts.

race57-015

Opposite retract.

race57-016

Small air cylinder in the wing center section will have to go.

race57-017

One down...and out.

race57-018

Oops...looks like a section of the top main spar is missing. That is a definite rework.

race57-019

Closer shot of the missing main spar with the air tank removed.

race57-020

A few screws for good measure I suppose.

race57-021

Screws after using the extraction device.

race57-023

this is what happened when I leaned on the wing a bit too hard...cracked the center section right in half.

race57-024

Another random screw.

race57-025

Center section somewhat cleaned up.

race57-026

Time to make a rib pattern before I remove too much.

race57-027

All cleaned out and ready for rebuilding. Notice that the wing spar joiners are dry as they were never epoxied in place.

race57-028

Two new ribs and a top main spar cut to size.

race57-029

Ribs and spar glued in place.

race57-030

Rebuilt center section from the rear.

race57-031

Sheeting started to shore up the wing a bit.

race57-032

New 1/8" ply joiner box sides cut to replace the balsa ones supplied in the original ARF.

race57-033

Joiner box sides epoxied in place.

race57-034

1/8" balsa vertical grain webs added to the remaining bays.

race57-035

Top right cap strips are missing and the second rib out needs the top replaced.

race57-036

Rib pattern made from the left wing to fix the right side. Cap strips in place as well.

race57-037

Replacing the CA hinges on the ailerons with Robart hinge points requires extra blocking.

race57-038

Top center section sheeting completed. Solid as a rock now.

race57-039

Time to strip the fuse while I wait on the retracts to arrive.

race57-040

The inside front of the fuse was fiberglassed...most of this will go away.

race57-041

Ahh, the elusive tailwheel retract servo. This will be relocated to an area that is accessible.

race57-042

Front end cleaned up and the top stringer placed for some support.

race57-043

Rear fuselage stringers removed.

race57-044

Drawing out the first new former.

race57-045

First former in place.

race57-046

No guts no glory...time to start cutting the turtledeck away.

race57-047

New formers and top stringer in place.

race57-048

Left side stringers back in place. Right side will remain open until all of the pushrods are routed.

race57-049

New cockpit area sheeting.

race57-050

Time to work on this bugger.

race57-051

Old tailwheel support former being removed.

race57-052

Down to whats left of the original former.

race57-053

The main stringers were cut out of the tail section which weakened it considerably.

race57-054

Right main stringer extended with a kerf joint.

race57-055

Left main stringer was cut back two formers and replaced.

race57-056

Shaping the new tailwheel former.

race57-057

Tailwheel mounted to the new former.

race57-058

New former in place.

race57-059

3/8" basswood servo rails epoxied in place.

race57-060

Making up the servo tray.

race57-061

Servo tray fastened to rails with 6 mounting screws.

race57-062

Tailwheel retract pushrod and steering pull-pull setup.

race57-063

Shot of the tailwheel with the linkages in place.

race57-064

Cleaning off the old sheeting.

race57-065

New sheeting in place as well as the pushrod housing for the elevator.

race57-066

Left side sheeting in place.

race57-067

Another shot of the sheeted left side.

race57-068

Remainder of the fuse front sheeting removed and firewall cleaned up

race57-069

Spacers for the rear of the firewall.

race57-070

Spacers glued in place.

race57-071

4" diameter 1/8" ply plate added to backside of firewall.

race57-072

Adding some meat back into the firewall for the correct mounting hole locations.

race57-073

Because I didn't originally put this ARF together, I've added a few epoxied dowels through the stab mounting plate for peace of mind.

race57-074

Original rudder/tailwheel servo bay sheeted over and sanded smooth.

race57-075

6" diameter 1/8" ply plate added to front side of firewall and motor mounted.

race57-076

View of the backside of the reworked firewall.

race57-077

Front view of the firewall. Should get plenty of cooling air movement.

race57-078

Laying out a former for the battery tray.

race57-079

Battery tray former glued in place.

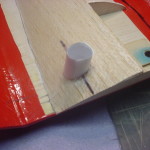

race57-080

Battery tray...the post will prevent the batteries from being pushed up against the motor mounting screws.

race57-081

Batt tray glued in place.

race57-082

Mock up of the 10S setup. A 6S will also fit on the tray.

race57-083

Right fuse side sanded and ready for sheeting.

race57-084

Right side sheeting in place.

race57-085

Bottom front sheeting in place.

race57-086

Time to close in the tailwheel a bit.

race57-087

Adding blocks for shaping.

race57-088

Rough shaped with a razor plane.

race57-089

Final sanded and ready for filler if needed.

race57-090

Final check fit of the fin/rudder before epoxying the fin in place.

race57-091

The rudder torque rod and tube will no longer be used so I will clean up the rudder leading edge a bit.

race57-092

1/4" removed from the leading edge and solid balsa glued back on.

race57-093

Robart hinge points will be used throughout the model.

race57-094

Marking the location of the rudder control horn.

race57-095

The ratty elevator leading edges will get the same 1/4" balsa replacement as the rudder.

race57-096

Tail surfaces all hinged and ready to go.

race57-097

The Lado electric retracts have arrived so its time to dig into the bottom side of the wing.

race57-098

The mechanical retract belcrank mounting plate will go away and that plywood main spar will have to be beefed back up to its former self.

race57-099

Digging down to the original gear mounts which are painted blue. The spray foam will go away as well.

race57-100

First wheel bay all cleaned up and ready to start over.

race57-101

Cutting out the built up radiator inlet.

race57-102

Rebuilding the leading edge at the radiator inlet. I will simulate these later with Monokote trim.

race57-103

These holes in the leading edge were needed to accept the plastic machine gun ports that came with the original bARF.

race57-104

No machine guns are needed for the Race 57. Some balsa dowel fills them in nicely.

race57-105

The original aileron servo mounting needs a little work.

race57-106

Reworked aileron servo mount.

race57-107

All necessary bottom sheeting removed and both wheel wells cleaned up.

race57-108

The original gear mounts don't have enough meat left on them to be of any use so they have to go and be replaced.

race57-109

Another shot of the gear mounts looking from the back.

race57-110

Digging out the old gear mounts.

race57-111

Belcrank mounting plate removed.

race57-112

Anything that I can pull up by hand is leaving.

race57-113

The original triangle stock will be used to reinforce the new gear mounting plate.

race57-114

New 3/8" aircraft ply mounting plate epoxied in place.

race57-115

Rebuilding the ribs around the gear mounts.

race57-116

Reinforcing the plywood spar that was previously chopped away.

race57-117

I have to assume the plywood joiner isn't glued inside the box since it wasn't in the center section. The outer ones aren't as easy to get at so I've drilled and epoxied 2 1/4" dowels through the joiner.

race57-118

Dowels sanded flush.

race57-119

Completed rework on the left side gear mount.

race57-120

1/16" balsa wheel well floor added.

race57-121

This rib needs touched up to accept sheeting.

race57-122

Good as new.

race57-123

Right side gear area gets the same treatment as the left. The Lado retract struts were too short for this model so I'll move back to the fuselage until longer struts arrive.

race57-124

A little rib reinforcing at the aft aileron servo hatch screws. These ribs tend to crack or break if you use too much pressure when installing the servo hatch.

race57-125

Starting the fuselage covering in the cockpit area.

race57-126

I find it easier to cover the edges of surfaces first so that you don't have to worry about overlapping the covering around curved areas.

race57-127

Elevator halves covered and ready for hinging.

race57-128

Corners and edges done first so that your cuts don't have to be exact every time.

race57-129

The fuselage will be covered in 3 pieces...one top center to bottom center on each side of the rear fuse and one to finish off the front.

race57-130

Left rear Monokote shrunk to fit.

race57-131

The front half is covered in one continuous piece with the seam on the bottom.

race57-132

Main fuse covering completed.

race57-133

Only one side of the tail feathers is covered before hinging so that I can inspect the glue joint on the hinges.

race57-134

Where possible I like to add an epoxy/milled fiberglass bump to the back side of the hinges for added security.

race57-135

Hard to see here but I put some grooves on the elevator joiner wire with a Dremel cut off wheel. These grooves will give the epoxy something to grab onto.

race57-136

Tail feathers hinged and covered.

race57-137

Fin/rudder tip trim.

race57-138

I've run some black Monokote through the Smart Stripe tool to make 1/8" stripe tape. Making your own from scrap covering saves money and the iron on covering will last longer.

race57-139

Laying out the starburst on the stabilizer.

race57-140

Making a pattern and cutting multiple trim pieces ahead of time makes life simpler. Just be sure to make mirror images of each piece where required.

race57-141

Stabilizer top.

race57-142

Stabilizer bottom.

race57-143

I used Autocad to trace all the markings from a downloaded picture of the Race 57 and then scaled them accordingly.

race57-144

Using the pattern to set a few benchmarks to place the markings.

race57-145

Here I've marked the edges of the 5 and 7 with a black Sharpie. When done placing the graphics, the Sharpie will wipe away with a little denatured alcohol.

race57-146

If you do a lot of iron on covering and don't have a mirror or piece of glass to work on, get one. It will make your life much simpler. I've ironed a piece of white Monokote down to the cleaned mirror and taped a pattern over it.

race57-147

After cutting out the graphic, remove the unwanted covering but don't disturb your graphic.

race57-148

Use masking tape to hold your graphics position and orientation.

race57-149

After peeling the graphic from the glass, tape it in position and run your iron right over the masking tape making sure to get the edges sealed good.

race57-150

Remove the masking tape and hit it with the iron again for good measure.

race57-151

More graphics cut out on the mirror...

race57-152

...and placed the same way as the 57

race57-153

Left side graphics and trim tape complete.

race57-154

The tail numbers were also drawn in Autocad and cut out of black Monokote.

race57-155

Motor and ESC mounted to the firewall.

race57-156

Battery wiring harness with a safety shunt and high voltage spark arrester.

race57-157

Outside view of the shunt/arrester.

race57-158

Elevator hook up.

race57-159

Rudder hook up.

race57-160

All pushrods hooked up to their respective servos.

race57-161

Fitting the P-51 style canopy.

race57-162

The fiberglass belly pan has some holes that need filled.

race57-163

Using an epoxy/microballoon mixture to fill the holes.

race57-164

The longer Lado struts have arrived so I can now build the wheel wells.

race57-165

The wheel well diameter works out to be a Sig Stix-it can. I've wrapped the bottom with paper and tape to build out flush with the lip on the can.

race57-166

Using 1/16"balsa for the wheel well walls.

race57-167

The bottom needs cut at an angle to fit properly in the wing.

race57-168

Vertical walls in place. I used the can while gluing in place to ensure it stayed as round as possible.

race57-169

A shot with the wheel retracted.

race57-170

Building out the strut tunnel.

race57-171

A little reinforcing for the fragile 1/16" balsa walls.

race57-172

Sanded to the wing contour and ready for sheeting.

race57-173

Left side sheeting completed. As I snapped this picture I realized I forgot to run the aileron servo extension wire...awesome. I was able to cut out the bottom of the strut tunnel and miraculously fish the wire through.

race57-174

Belly pan filler sanded smooth and ready for paint.

race57-175

Second wheel well completed...this time with the aileron servo extension wire in place the first time.

race57-176

Masking off the cowling.

race57-177

Masking off the canopy.

race57-178

Cowl painting completed.

race57-179

I used 1/8" vinyl trim tape for the cowl so I didn't have to run the iron over the fresh paint job.

race57-180

Embedding some 1/4" aircraft ply in the ailerons to mount the control horns to.

race57-181

Completed fuselage...turned out nice.

race57-182

Close up of the canopy area.

race57-183

Right top wing sunburst pattern.

race57-184

Bottom center section will be left uncovered until the fiberglass belly pan is mounted.

race57-185

Bottom left wing sunburst pattern.

race57-186

Top left wing striping tape and graphic completed.

race57-187

Completed top right wing.

race57-188

Bottom left wing graphics and servo hookup.

race57-189

Well that's disappointing....fiberglass belly pan doesn't mate up to the fuselage.

race57-190

Time to break out some more balsa and make a new belly pan.

race57-191

Rear belly pan former glued in place.

race57-192

Laying out the remaining formers using the fiberglass part as a guide.

race57-193

All formers and center stringer in place and ready for sheeting.

race57-194

First half of sheeting glued in place.

race57-195

Wing bolt hole cut and paper tube glued in place.

race57-196

Paper tube cut and sanded flush with the belly pan.

race57-197

Remaining half of sheeting glued in place.

race57-198

Now that's a much better fit.

race57-199

Lado retracts mounted for the last time.

race57-200

Finished product ready for delivery.

race57-201

Right side view.

race57-202

Left side view.

race57-203

Left rear quarter view.

One Response to “Race 57 Super Corsair”

Leave a Reply

Please note: Comment moderation is currently enabled so there will be a delay between when you post your comment and when it shows up. Patience is a virtue; there is no need to re-submit your comment.

Whoa! What a beautiful conversion. Brent you are a true artist. The attention to graphic excellence is quite remarkable. Love the belly pan rebuild. The original just didn’t cut it. The wheel well rebuilds are super strong and better than new. The whole plane is a work of art and its .60 size airframe will really stand out in the air.